EXAMINATION OF SOIL MEASUREMENT AND SOIL FOCUS FOR THE PRODUCTION OF SOIL FRUIT

EXAMINATION OF SOIL MEASUREMENT AND SOIL FOCUS FOR THE PRODUCTION OF SOIL FRUIT

Abstract

Biometric indicators of soybean plants of various varieties for 20 years, selected from farms of various municipal districts and districts of the Amur region are researched. The chemical composition and content of fiber, protein, nitrogen-free extractive substances of straw during decomposition in the soil provides high nutrition for living soil organisms. It is analyzed that soil biota, which destroys the biological mass of the soy root system and stems, forms substances necessary for the growth and development of plants and contributes to increasing the yield of crops in crop rotation. After the death of the root systems and decay of the remnants of the root, the resulting pores serve as moisture conductors to the upper of the arable layers and increase the water permeability of the soil, which contribute to the deep penetration of the root system of the subsequent culture into it. Criteria for optimizing the size of the crushed soy straw particles, for optimal soil decomposition, and the length of the particles is equal to 100 mm with a content in the total crushed pile of up to 90% are justified. The use of the cutting segment of the harvester is proposed for grinding. Grinding knives on the rotor drum are placed bi-directionally along the screw line, where each first row is balanced by the corresponding working body of the second row. Two-stage and uniform placement of the working organs around the circumference of the grinding drum provides a decrease in the pulsation of the load. It is established that soybean in the Amur region, at present, still dominates the structure of field crops and occupies up to one million people. It increases the index of technological efficiency of cultivation, which in the four years of the current five-year plan increased by 1.25 times compared with the previous five-year plan. In which, along with other indicators of intensification of crop production, a significant role is played by grinding soybean stems by 90% with a particle length of 100 mm and their soil sealing.

1. Introduction

The Amur region ranks first for soybean production in the Far Eastern Federal District, produces 68% of the gross volume of soybeans in the Far Eastern region, and remains one of the main regions producing soybeans in Russia, growing 23.6% of the gross volume of soybeans from the all-Russian indicator. The increase in demand for soybeans as raw materials for further processing in various directions contributes to the growth of the area under soybeans in the Amur region to one million tons... in the structure of crops is (63.1%), an increase in the area under crops of this culture is noted in other regions of the Russian Federation , .

Improving soil fertility and arable productivity through science-based farming systems is the primary objective of agricultural production , . The joint application of mineral and organic fertilizers contributes to the expanded reproduction of the fertility of the meadow black-earth soil. Soy provides itself with nitrogen up to 80% due to symbiosis with tuber bacteria, which requires the creation of conditions for their active reproduction and growth , , therefore, the technologies of cultivation of crops with saturation of the arable layer with organic matter , acquire special relevance. The most important indicators of soil fertility include the content of humus and other available nutrients formed by the transfer of food energy from its source through a number of organisms at various trophic levels in the ecosystem. At the same time, the level of realization of the potential yield of soybean varieties in the production conditions of the Amur region increases by 7% .

Source of plant nutrition — atmosphere (solar energy) water and soil. Soil organisms that destroy biological mass form nutrients for plant growth and development . Technological impact, aimed at maintaining the vital activity of these organisms, significantly increases the content of mineral nitrogen and mobile phosphorus in the soil increases soil fertility and, accordingly, the yield of cultivated crops. Strengthening the work of free-living, associative and endogenous microorganisms allows you to include in the biological cycle an additional number of biogenic elements from the air and compounds inaccessible to plants.

When harvesting soybean leaf beans, the crushed part of the stems and weeds are thrown onto the soil. Organic impurities are sealed in the soil by destination or cultivation in order to return nutrients to the soil microflora. The intensity of decomposition of straw and floor by microorganisms in the soil depends on the degree of grinding of stems and leaves and the uniformity of their distribution over the field. The improvement of the process of grinding and scattering of soy straw for decomposition in the soil and creating conditions of stability and subsequent growth and development of cultivated plants is solved by developing high-quality shredders .

Purpose of research: development of a soy straw shredder with a capacity of 90% by the yield of crushed particles up to 100 mm long, providing intensive decomposition of straw by microorganisms in the soil when it is closed by cultivation or dishing, ensuring the reproduction of soil fertility.

2. Research methods and principles

The objects of research are soybean plants and devices for their grinding and scattering. Biological yield of grain and non-grain part of soybean plants of cultivated varieties in the fields of the Amur region for a long period of 20 years was studied. Using the infrared scanner "FOSS NIRSistems 5000" studied the chemical composition of the stalks and leaves of soybeans Sentyabrinka. Soya was harvested by harvesters with stationary and segment type grinders in the fields of the FGBNU FNC VNII Soy and other farms in 2000–2025 and determined the biometric indicators of soybean plants, biological yield, yield structure with the reduction of soybean seeds to the standard humidity of 14%.

The straw and small straw pile coming down from the gratings of the cleaning and the copier were analyzed for the frequency of variation in the resulting sizes of straw and floor particles. Histogram of variation of sizes of straw particles and low coefficient of breaking of straw (0,527) by the threshing machine of the combine, determines need of improvement of the device for grinding of non-grain part of harvest of soybean (stems and leaves) both for consumption in animal husbandry, and for soil sealing.

To conduct research, a prototype soybean straw shredder was manufactured for a grain harvester, including a shredding and scattering-dispersing device. The prototype was made in the experimental workshop of the laboratory of mechanization and automation of crop production FGBNU FNC VNII Soy and delivered to the test site in assembled form by road.

The optimization criterion for the qualitative soil decomposition of crushed soy straw particles is adopted: the specific weight of crushed straw along the length of the particles up to 100 mm, amounting to 90%. The weighted average size of the crushed particles of soybean stalks, depending on the number of grinding working organs and the angular velocity of the drum, was determined according to the developed method of conducting the experiment.

Soy is an annual plant with a stem height, in the production conditions of agricultural enterprises of the Amur region of 60 cm with a growing period of 90 to 115 days, with a strong erect stem and a rod branching root. The stem and branches are straight or cranky, different in thickness: from thin (3...4 mm) to more thicken (6...9 mm). The number of branches is from 2 to 5, and the height of their location from the root neck varies from 30 to 80 mm depending on the variety and growing conditions (temperature and soil moisture).

Processing of experimental data on the biological yield of soybeans showed variability in the mass of straw and floor (table 1). The weight of straw varies from 0.53 to 0.198 kg / m2, the floor (mainly flaps) from 0.043 to 0.163 kg / m2 with a relative error of the sample average straw of 9.2% and the floor of 8.42%. The biological yield of the non-grain part of the soybean crop (straw and floor) shows that the total weight of straw with 1 m2 is 1.4 times higher than the weight of the floor (stem), which, unlike the stems, practically does not require additional grinding.

Plants on the output of straw and floor to soy grain are the following ratio1:0.68:0.49. Or for each ton of grain in soy fields, up to 1.2 tons of plant mass are grown, which, with high-quality grinding and soil sealing in the autumn to a depth of 10...14 cm, replenishes the soil with plant residues and contributes to maintaining soil balance in the ecological system and increasing crop yields.

Table 1 - Results of studies of biometric indicators of soybean plants by varieties for the period of harvesting

Year of soybean harvest | Soybean varieties | Mass of sheaf (kg) and number of plants (sh) from 1 m2 | Mass of grains, kg | Mass of straw, kg | Mass of gender, kg | Exit of straw to grain, % | Yield of the floor to the grain, % | Height of stems, cm |

2000 | VNIIS-1 | 0.637/56 | 0.276 | 0.198 | 0.163 | 71.7 | 59.0 | 78.0 |

2001 | VNIIS-1 | 0.404/56 | 0.176 | 0.137 | 0.091 | 77.8 | 51.7 | 68.0 |

2002 | VNIIS-1 | 0.419/55 | 0.179 | 0.155 | 0.085 | 86.5 | 47.5 | 69.0 |

2003 | Sonata | 0.473/62 | 0.196 | 0.176 | 0.101 | 89.7 | 51.5 | 45.0 |

2004 | Harmony | 0.374/80 | 0.165 | 0.110 | 0.099 | 48.5 | 47.9 | 40.0 |

2005 | VNIIS-1 | 0.528/86 | 0.224 | 0.193 | 0.111 | 86.1 | 49.6 | 69.0 |

2006 | Harmony | 0.409/59 | 0.193 | 0.129 | 0.087 | 66.8 | 45.1 | 48.0 |

2007 | Sonata | 0.402/68 | 0.195 | 0.115 | 0.092 | 58.9 | 47.1 | 41.0 |

2008 | Harmony | 0.428/78 | 0.225 | 0.107 | 0.096 | 47.6 | 42.6 | 51.0 |

2009 | Harmony | 0.431/78 | 0.230 | 0.119 | 0.082 | 51.7 | 35.6 | 51.0 |

2019 | Dauria | 0.223/56 | 0.105 | 0.075 | 0.043 | 71.4 | 40.9 | 65.0 |

2019 | Lydia | 0.247/44 | 0.108 | 0.087 | 0.052 | 80.5 | 48.1 | 70.9 |

2019 | September | 0.270/58 | 0.152 | 0.053 | 0.065 | 35.0 | 43.0 | 49.3 |

2019 | Kitrosa | 0.414/44 | 0.197 | 0.095 | 0.122 | 48.2 | 62.0 | 103.1 |

2020 | Bonus | 0.348/59 | 0.161 | 0.127 | 0.060 | 79.2 | 37.6 | 59.0 |

2021 | September | 0.579/31 | 0.231 | 0.197 | 0.151 | 30.3 | 48.6 | 90.3 |

2025 | September | 0.552/31 | 0.273 | 0.137 | 0.135 | 50.1 | 49.5 | 61.5 |

2025 | Topaz | 0.524/37 | 0.,252 | 0.145 | 0.130 | 57.5 | 51.5 | 68.2 |

Average 2000-2025 | 0.439/60 | 0.196 | 0.131 | 0.095 | 66.8 | 48.5 | 62.6 | |

S | 0.046 | 0.043 | 0.029 | – | – | – | ||

V, % | 24.59 | 34.4 | 31.52 | – | – | – | ||

S х % | 6.57 | 9.19 | 8.42 | – | – | – | ||

Note: 2008-2025

The main nutrient included in the composition of soy straw and leaves is fiber (table 2). Its content in the stalks and leaves of soybeans is 35...35.2% of absolutely dry matter. The composition of the stems and leaves includes nitrogen-free extractive substances, which account for 37.3...40.8%, their group consists of sugar, starch, hemicellulose, pectin substances, pigments, resins, tannins, organic acids. Higher nitrogen content in soy straw increases cellular protein synthesis by microorganisms and accelerates the decomposition of soy straw. The period of decomposition of soybean straw increases with its large grinding, therefore, to increase the number and diverse species composition of cellulose-destructive bacteria and fungi, it is necessary to ensure its finer grinding. Cellulose-destroying microflora is enriched with bacteria that release abundant mucus, which is weakly susceptible to destruction by other soil microorganisms and aggregates are formed in the soil that retain their lumpy structure.

Table 2 - Chemical composition of the stalks and leaves of the soy variety Sentyabrinka

Indicator | Nutrient content, % ASB | ||||||||

Proteins | Fat | Fiber | BAV | Dry matter | Са | К | Мg | Р | |

Stealth | 5.2 | 1.05 | 35.0 | 37.3 | 93.4 | 1.2 | 1.44 | 0.29 | 1.05 |

Doors | 3.4 | 0.8 | 35.2 | 40.8 | 92.7 | 1.1 | 1.58 | 0.28 | 0.79 |

Soy straw and leaves are characterized by a low content of raw and digestible protein (3.4...5.2%), they are also poor in fat (1.05...0.8%). The volumetric weight of the floor is up to 80 kg / m3 — this is an order of magnitude lower than the volumetric weight of soybean grain. Due to the low-volume weight, the soy floor has a low transportability, which complicates the mechanization of its cleaning and transportation to livestock complexes. Cleaning of straw and flooring from fields and delivery to livestock complexes are complex and time-consuming operations. At the same time, on the territory of livestock complexes it is necessary to have large areas for its storage with ensuring the conditions for the preservation of nutrients (covered storage with ventilation), which is economically unprofitable. Soy straw and floor cleaning in the farms of the Amur region is zonal in nature, and it is associated with the presence of cattle in a particular farm. Cleaning of straw must be carried out for the timely implementation of subsequent agricultural techniques of soil treatment. Therefore, there is a need for various options for the development of higher-quality grinders, with the achievement of certain sizes of crushed soy straw fractions, effective for nutrition and reproduction of soil microflora, ensuring the restoration and expanded reproduction of soil fertility.

The issue of grinding the straw of grain crops and the development of shredders is devoted to many scientific works from which conclusions have been drawn that an even spread in width and the degree of grinding is not ensured. And when developing soy straw shredders, larger in thickness and stronger in structure, it is additionally necessary to take into account the dense structure of soy stems and the features of the structure of the soy stem to be crushed.

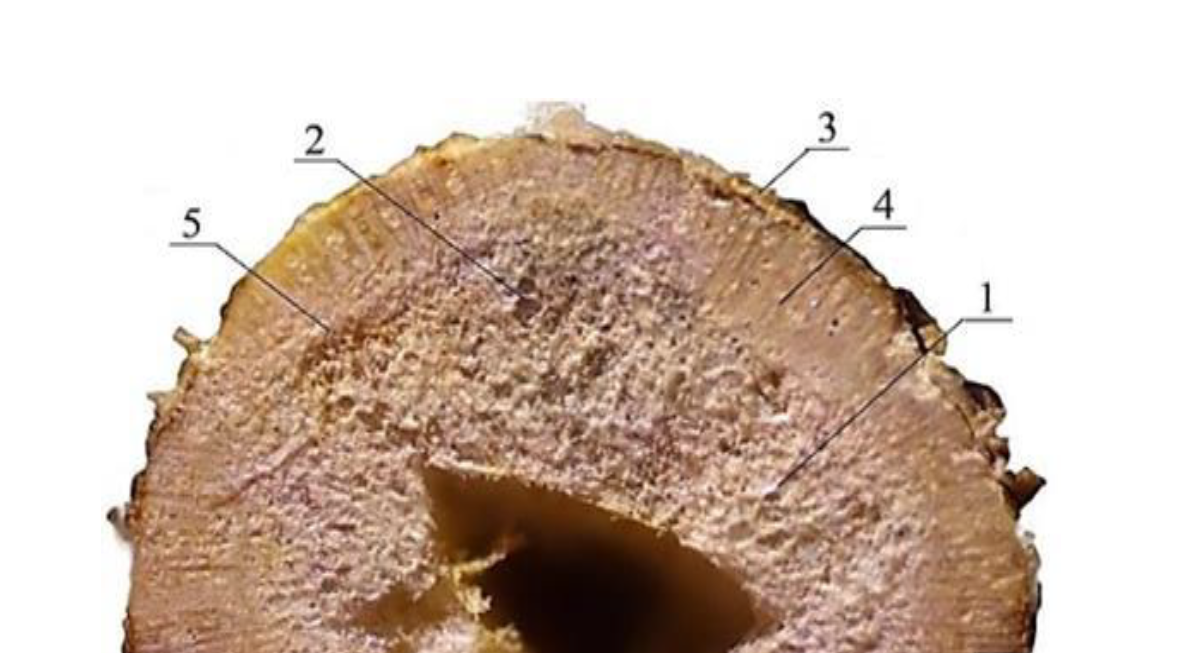

The primary hollow stem of soy (Figure 1) consists of a heart-shaped parenchyma 1, which does not contain chloroplasts, the zone located in the circle of the vascular bundles 2, the epidermis 3, the cortical layer between the vascular bundles and the epidermis.

Figure 1 - Cross-section of a hollow soy stem at the root neck:

1 – heart parenchyma; 2 – vascular bundles; 3 – epidermal cortex; 4 – wood sclerenchyma; 5 – xylem

Such a dense structure of the structure of soy stems reaching up to 8...9 mm in diameter at the root neck and a powerful soy root system provides a high degree of resistance of soy plants to harvesting, prevents moisture from over wetting the fields and complete preservation of the harvest to harvesting and requires an increase in energy consumption for grinding the stems while improving the design of the shredders and obtaining certain sizes of the corresponding fraction of soy straw, ensuring soil decomposition at the depth of the ground into the soil.

Studies conducted in 2022 to assess the quality performance of the grinders of modern serial combine harvesters RSM-101 "Vector 410" with a period of operation of 2...4 years in the harvesting of soybeans equipped with a shredder-spreader, showed that the mass fraction of fractions in length up to 100 mm reached 79.05% (table 3), this degree of grinding of soybean straw is insufficient for effective soil decomposition.

Table 3 - The degree of grinding of soy straw during harvesting combines RSM-101 "Vector"

Fraction of crushed straw, mm | l<10 | 10≤l<20 | 20≤l<50 | 50≤l<100 | 100≤l<150 | 150≤l<200 | l>200 | Total |

Massa, g | 311.1 | 123.1 | 494.2 | 296.8 | 440.1 | 82.8 | 148.0 | 1896.1 |

Mass fraction of fraction, % | 16.4 | 6.49 | 26.06 | 15.65 | 23.22 | 4.36 | 7.82 | 100 |

Contents Faction less and more 100 mm, % | 64.6 | 35.4 | ||||||

3. Main results

The results of the average multi-year values of the fractional composition of the soy flour, descending from the wind-grid cleaning of the combine, showed that the floor pile is a complex mixture consisting of different particle sizes, and its main components are frayed stems, crushed leaves, leaves, seeds of weeds by 30.5%, as well as whole leaves of beans, finely milled stems and weeds, which are 45.1% and almost 25% consist of large parts of straw and weeds. This size of the listed parts of straw and flooring is not completely covered by the soil during subsequent processing by disking or cultivation and inhibits the decomposition of straw.

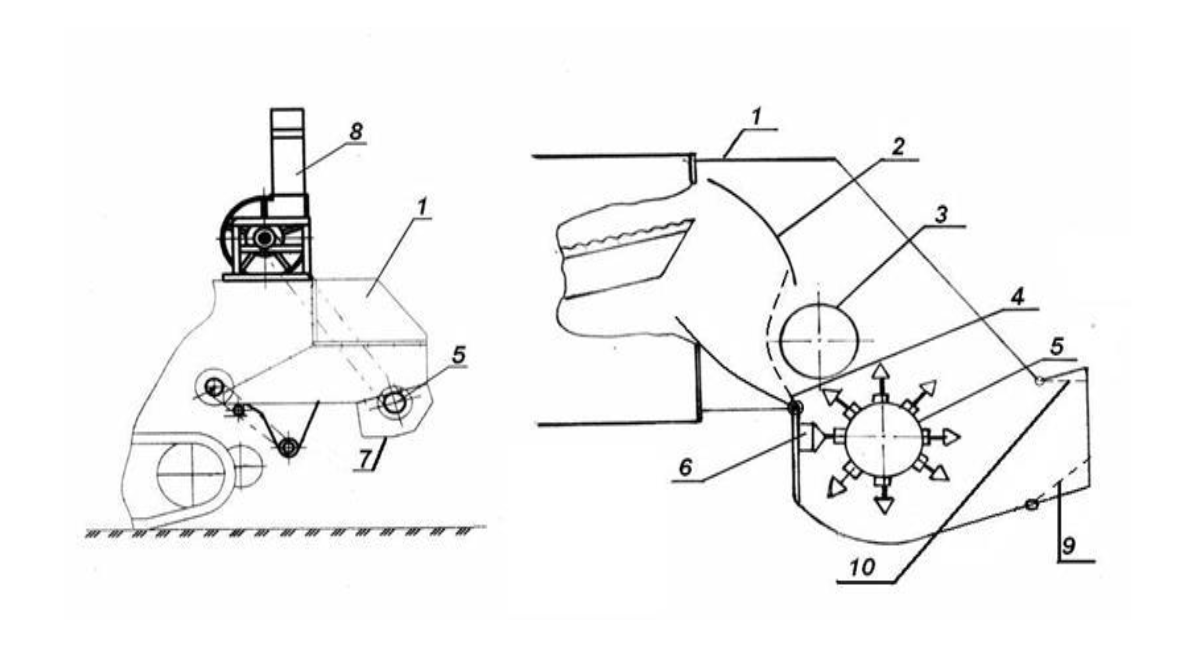

The analysis of structural and technological schemes of grain straw shredders and spreaders contributed to the development of the soy straw shredder "IRVS-1200R", the scheme of which is presented in figure 2. Grinding attachment, aggregated with harvesters "Yenisei".

Figure 2 - Scheme of shredder-spreader of soy straw roller "IRVS-1200":

1 - frame; 2 - reflective screen; 3 - compacting drum; 4 - straw guide; 5 - rotor drum with grinding knives; 6 - hinged cutting bar; 9, 10 - adjustable thrusts of the guides

In the cross-section, the second row of grinding working organs is offset from the first row by 180°, that is, each working organ of one row is balanced by the corresponding working organ of the other row. The working organs on the grinding drum 5 are located on a two-stage screw line.

This arrangement of the working organs reduces the dynamic loads on the shaft of the rotor drum, since in cross-section each subsequent working organ of the series is shifted in circumference relative to the previous working organ of the same series at an angle ß = 360 / m. The working organs of both rows are arranged in a circle uniformly and at a distance of 50 mm. At a certain point in time, only one working organ interacts with the crushed mass, which ensures a decrease in the pulsation of the load.

The cutting beam is a box-shaped beam of square section, on which the knives are fixed. The cutting bar is hinged to the shredder frame and can be rotated relative to the axis. Changing the position of cutting knives in the working area is the adjustment of the cutting height and the degree of grinding of straw.

The crushed mass of straw, the air stream generated by the drum of the grinder, moves and is distributed over several streams in the lower boards 9 and is distributed to the guide boards of the spreader 10 and spreads out and flies out and settles on the field at a given width. The width of the spread of crushed straw consists of the sum of the deviation values at the exit from the left and right chandeliers and the constructive width of the shredder. With an increase in the rotational speed of the rotor of the grinding drum from 1600 to 2400 min-1 and the angle of installation of the guides from 20 ° to 70 °, the deviation of the crushed particles varies from 0.6 to 1.8 m at an air flow rate of 3 m/s and from 2 to 3.4 m at a speed of 7 m/s. The width of the scattering of crushed soy straw particles at an air flow rate of 3 m/s and the angle of the guides from 20 ° to 70 ° increases from 2.4 to 4.9 m, and at an air flow rate of 7 m/s at the same angles of the guides from 5.2 to 7.9 m.

4. Discussion

Figure 3 - Grinder - spreader - straw roller "IRVS-1200" in the aggregate with the grain harvester "SZK - 1200 RAG"

Table 4 - Specific weight of straw by fractions obtained from combine harvesters with shredders "IRVS-1200" and "KDM 0-27"

Indicators | Specific weight, % | ||

IRVS-1200 | "KDM 0-27" | ||

Shredded soy straw fractional composition, mm | 0…25 | 45.2 | 28.0 |

26…50 | 17.8 | 23.5 | |

51…75 | 22.4 | 18.5 | |

76…100 | 6.1 | 4.3 | |

>100 | 8.5 | 25.7 | |

The task of modern nature management is the development and implementation of farming systems that allow for the highest possible natural-anthropogenic compatibility in the system of rational crop rotations, which, in combination with grinding and soil sealing of straw, increase important environmental factors affecting soil biological self-regulating mechanisms.

The dynamics of the change in the ratio of field crops in crop rotation is determined by the introduction of short-rotation crop rotations, which allow increasing the area under soybeans and, in combination with the use of effective technologies, new varieties, grinding and fixing straw, due to the production of plant mass, the yield and gross harvest of soybeans annually increase and improve the economic indicators of the crop rotation area (table 5). The index of technological efficiency of soybean cultivation for the four years of the current five-year plan increased by 1.25 times compared to the four years of the previous five-year plan.

Table 5 - Sown area, gross harvest and soybean yield in the Amur region for 2014-2024

| 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 |

Sown area, thousands. ha | 766.3 | 892.3 | 901.4 | 964.3 | 988.8 | 869.9 | 844.5 | 769.4 | 861.6 | 898.7 | 908 |

Gross revenue, thousands. tonnes | 996.9 | 1009.8 | 925.7 | 1265.4 | 1055.3 | 863.2 | 978.6 | 1138.6 | 1560.3 | 1427.3 | 1417 |

Yield, c/ha | 13.4 | 11.4 | 10.3 | 13.3 | 12.6 | 13.2 | 13.0 | 15.7 | 18.2 | 15.9 | 15.6 |

5. Conclusion

The development of soybean harvesting technology using high-quality soybean straw shredders, spreading straw and flooring to the width of the harvester and sealing in the soil layers to a depth of 10–14 cm creates conditions that increase the activity of the plant-microbial complex in the soil, contributing to the improvement of its structure, increase yields and gross harvests of grain crops and soybeans.