IMPROVING THE CLEANING OF THE COMBINE OF TWO-FASE REFERENCE TO SOYA SEEDS

IMPROVING THE CLEANING OF THE COMBINE OF TWO-FASE REFERENCE TO SOYA SEEDS

Abstract

The paper considers the technological process of air-grid cleaning of a grain harvester of two-phase milling. The ways of separation of small soy pile in the combine of two-phase milling when obtaining the seed and commodity fraction of soybean grain are shown. To improve the cleaning of the combine harvester when receiving the seed and product fraction, a constructive solution was proposed to improve the shape and size of the shutters of the upper grille of the harvester, allowing to intensify the process of separation into fractions of a small soy pile. Installation of additional shock board, a small soy bag, threshed with the second drum and coming from the straw shaker and the domestication device on the second part of the grille, provides high-quality cleaning of the first seed fraction. Tremendous boards, making an oscillating movement, carry out the movement and simultaneous stratification of the soybean pile into two main layers: the upper straw with low density and the lower, containing ground soy grain.

Separation into two parts of the harvester slat treatment plant for separate separation in the first half of the soy pile slats, after being hammered with the first threshing drum. The other half of the grille is flooded with three streams: the first through the grating under the drum of the threshing machine, the second from a straw shaker and the third from a household appliance. The developed technology of separate feeding of small soy pile on the first and second half of the rack mill cleaning station reduces the load on the first part of the rack and provides a better release of soybean grain of the first fraction in purity by 99,8%.

1. Introduction

The development of a new method for obtaining soybean seeds with a shortened logistical path directly in the combine of two-phase threshing provides for the division of air-grid cleaning of the combine into two parts. In the first half of the mill, a small pile of soybeans is separated, coming from the main concussive board of the combine, after threshing and separation of seeds with the first threshing drum. At the same time, to reduce the crushing of soybean grain during threshing, the rotation frequency of the first threshing drum is reduced to 280 min-1 . To prevent mixing of low-crushing separated seed grain, a small pile of soy has been milled after grinding with the first threshing drum and hammered with the second threshing drum under more severe conditions, coming from the first and second drums on the rack of the combine, they are separated .

For this purpose, in the combine of two-phase milling for the output of the first seed fraction, the parameters of an additional transport shaking board equal to 1000 mm and extending beyond the main rumble by 300 mm are determined, ensuring the removal and supply of soy powder after the second threshing drum to the second half of the rack mill cleaning station .

On the second half of the rack of the harvester cleaning, a small soy pile comes from the additional shaking board, consisting of three streams; the first through the grating under the drum of the second threshing and separation device, the second is from the straw shaker and the third is from the house-handling device .

The cleaning system consists of a shaking board for transporting small soy piles, sieve camp, it consists of two adjustable bars (upper with an extension cord and lower), fan and three screws to move the seed, grain to the bunker and beans to be ground again. At the end of the main and additional shaking board, fingers are installed to support large straw particles .

The shaking board makes an oscillating motion with a toss of wood toward the sieve. At the same time, in a row, with the movement of the heap, its simultaneous stratification into two main layers: the upper straw with a large fraction of particles; the lower is a mixture of grain, inorganic impurities, and small fraction of leaves, beanstalks and leaflets. Partly divided into two layers, a small pile of soy at the end of the concussive board descends on the fingers.., and the bottom layer, enriched with grain, wake up on the second floor... The separated particles of the upper layer are picked up by the air flow from the fan. Unrefined beans linger on the grille extension, installed at a small angle to the upper sieve. The gap in the shutters of the extension cord ensures the passage of unrefined beans to the colossal auger for repeated threshing. Light particles are carried out by air flow, and the remaining parts of the floor come down from the sieve and are thrown onto the soil , , , .

The two cleaning bars are the same, they differ in the size of the curtains. On the upper rack of the harvester, the teeth of the blinds are larger, than on the lower, because the upper sieve receives a larger soy pile. On the lower sieve, the passage of grain from the small pile is separated.

The air-grid cleaning of the combine works effectively on the harvesting of crops and soybeans on the basis of appropriate adjustments: the changing speed of air flow, angle of opening of blinds and angle of installation of extension cord, as well as an increased tooth length of the upper sieve blinds.

Purpose of the study – to determine the biometric indicators of soybean plants of various varieties, mass fraction and degree of grinding of small soy pile, descending from the harvester cleaning grill with two-phase threshing with bill drums and assess the quality of grain cleaning by the content of weed impurities and crushing at soybean harvesting when obtaining seed and commodity fractions in a converted harvester.

2. Research methods and principles

Studies were conducted in 2021-2022 in the laboratory of mechanization and automation of crop production FGBNU FNC VNII Soy, where the object of study was the varieties of selection of the VNII of soybeans, these are defined as:

- biometrics: the height of the plant, number of branches, attachment height of lower bean, number of beans and seeds per plant, stem thickness at the root neck, in the middle and at the end of the plant;

- the cut and structure of the soybean stem was studied with the Levenhuk D740T microscope, with data transmission to a computer;

The content of weed impurities was determined according to GOST R 52325-2005 «Seeds of agricultural plants. Variety and seed quality. General technical conditions».

The speed of air flow at different points of the sieve along its length was studied at a laboratory installation, made of natural harvester cleaning system, in the lumen of the rows of petals and at the base of the petals using a thermoanemometer DT-8880.

The assessment of the degree of grinding of soybean straw was carried out according to the following method: when passing by a combine harvester in the levee zone from the trellis mill, the floor was collected into soft containers. Next, the samples were sifted through a sieve with square holes of size 10, 20 и 50 mm, the received fractions were weighed. 50 mm long floor particles, 100, 150 and 200 mm separately separated by hand and weighed. Thus, was obtained a mass content of straw fractions of the sex of different lengths, coming down from the harvester’s trellis.

3. Main results

Soy is an annual plant, with a height of 406,5 before 712,6 mm, with a growing season of up to 120 days, with a strong straight stem, the rod, well-branched root, Reaching deep into the soil, Up to 1,5 m.

Stem and branches straight or cranked, different in thickness: from thin (3-4 mm) to more thickened (7-8 mm). Branches are more often from 2 to 5, and their height varies from 30 mm to 60 mm depending on the variety and growing conditions.

Based on years of research, conducted in the FGBNU DalNIIMESH and VNII soy grain output, stalks and floors with 1 m2 of accounting area to soybean seed varieties in terms of production on soybean fields of the Amur region is an average of 65,7 и 48%, with VNIIS varieties – 1 - 86,1 and 49,6%, Sonatas – 74,3 and 49,3%, The Harmony – 53,6 and 42,8%, Lydia – 80,5 and 48,1%, Kitrosa – 48,2 and 62,0%.

Table 1 - Ratio of stalk and leaf yield per cent to soybean grain of different varieties

Year of soybean harvest | Soybean varieties | Number of plants (s) with 1 m2 | Mass of grain, kg | Mass stalks, kg | Mass doors, kg | Output of stems to the grain, % | Output of doors to the grain, % | Height of stems, sm | |

2000 | VNIIS-1 | 56 | 0,276 | 0,198 | 0,163 | 71,7 | 59,0 | 78 | |

2001 | VNIIS-1 | 56 | 0,176 | 0,137 | 0,091 | 77,8 | 51,7 | 68 | |

2002 | VNIIS-1 | 55 | 0,179 | 0,155 | 0,085 | 86,5 | 47,5 | 69 | |

2003 | Sonata | 62 | 0,196 | 0,176 | 0,101 | 89,7 | 51,5 | 45 | |

2004 | Harmony | 80 | 0,165 | 0,110 | 0,099 | 48,5 | 47,9 | 40 | |

2005 | VNIIS-1 | 86 | 0,224 | 0,193 | 0,111 | 86,1 | 49,6 | 69 | |

2006 | Harmony | 59 | 0,193 | 0,129 | 0,087 | 66,8 | 45,1 | 48 | |

2007 | Sonata | 68 | 0,195 | 0,115 | 0,092 | 58,9 | 47,1 | 41 | |

2008 | Harmony | 78 | 0,225 | 0,107 | 0,096 | 47,6 | 42,6 | 51 | |

2009 | Harmony | 78 | 0,230 | 0,119 | 0,082 | 51,7 | 35,6 | 51 | |

2019 | Dauria | 56 | 0,105 | 0,075 | 0,043 | 71,4 | 40.9 | 65 | |

2019 | Lydia | 44 | 0,108 | 0,087 | 0,052 | 80,5 | 48,1 | 70,9 | |

2019 | September | 58 | 0,152 | 0,053 | 0,065 | 35,0 | 43,0 | 49,3 | |

2019 | Kitrosa | 44 | 0,197 | 0,095 | 0,122 | 48,2 | 62,0 | 69,1 | |

2021 | September | 56 | 0,300 | 0,091 | 0,146 | 30,3 | 48,6 | 49,3 | |

Average 2000-2019 г.г. |

х | 60 | 0,187 | 0,125 | 0,092 | 65,74 | 48,0 | 58,1 | |

– | S | – | 0,046 | 0,043 | 0,029 | – | – | – | |

– | V, % | – | 24,59 | 34,4 | 31,52 | – | – | – | |

– | S х,% | – | 6,57 | 9,19 | 8,42 | – | – | – | |

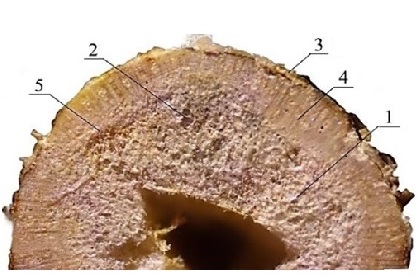

Figure 1 - Transverse cut of the hollow stem of the soybean at the base of the root neck

Note: 1 – heart parenchyma; 2 – vascular bundles; 3 – epidermal cortex; 4 – tree sclerenchyma; 5 – xylem

Stem vascular bundles are concomitant with xylem 5, extended to the core, floem, extending to the crust and a band of potential cambium cells between them. As the soybean plant develops, the stem undergoes a secondary growth phase, and additional vascular and supporting tissues appear: to the tissues of the cambium between the xylem and floem the tissue of the secondary xylem and phloem is added.

In regions of soybean cultivation with significant secondary stem growth, hollow stem formation is observed. Wood sclerenchyma is the hardest part of the stem, ensuring the strength of the stem prior to harvesting and bending resistance during threshing.

Table 2 - Results of studies of biometric indicators of soybean plants during harvesting (2008 2021 gg.)

Snope selection date | The place of selection of snobs | Class | Average height of plants, mm | Thickness of stems, mm | ||

on grounds of | in the middle | at the end | ||||

29.09.08 | OPH VNII soy | Grace | 534 | 4,10 | 3,64 | 2,75 |

30.09.08 | Agrofirm «Partizan» | Lydia | 511 | 3,95 | 3,34 | 2,75 |

07.10.08 | OAO «Dimskoye» | Harmony | 510 | 5,44 | 4,37 | 3,05 |

14.10.08 | «The Amur Mis» | Harmony | 712,6 | 8,0 | 6,08 | 4,85 |

10.10.09 | OAO «Dimskoye» | Lydia | 503 | 3,71 | 3.26 | 1,87 |

11.10.09 | OAO «Priamurie» | Dauria | 408,5 | 4,15 | 3,98 | 1,72 |

11.10.09 | OAO «Priamurie» | Lydia | 626,8 | 3,43 | 3,13 | 1,92 |

12.10.09 | OAO «Dimskoye» | Dauria | 406,5 | 4,01 | 3,72 | 2,1 |

27.09.19 | OPH VNII soy | September | 492,0 | 4,18 | 3,5 | 2,6 |

01.10.19 | OPH VNII soy | Lydia | 709,1 | 7,2 | 4,96 | 3,2 |

09.10.19 | OPH VNII soy | Dauria | 654,6 | 6,81 | 4,5 | 2,0 |

16.10.19 | OPH VNII soy | Kitrosa | 668,9 | 7,0 | 4,5 | 3,1 |

29.09.20 | OPH VNII soy | September | 625 | 7,4 | 5,2 | 3,0 |

23.09.21 | OPH VNII soy | September | 525 | 7,0 | 5,0 | 3,0 |

Soybean plants differ sharply from plants of colosals crops in physical and mechanical properties. Their characteristic feature is the presence of stems, nodes, where the leaves are, branches and organs of fruiting and beans, with branches formed by nodes only in the lower part of the stem . In the nodes of the upper part of the stem of the Amur and Primorsky varieties of soybeans there are no branches. In every node, usually, there is one branch (escape) . Due to the presence of lateral shoots, the leaves and beans are unevenly arranged along the nodes of the stem, Up to 80% of them are in the lower part of the stem.

The results of the study show, what a little pile of soy after being threshed with threshing drums of the bill type, coming from the trellis of the converted combine harvester is a complex mixture, consisting of crushed stems, whole and crushed leaves and leaves, weeds and inorganic admixture, of different sizes and contents (table 3).

Table 3 - Fractional composition of small soy pile, coming of the trellis of a converted harvester

Name of factions | Length, mm | Contents, % | Extent of grinding |

Worn-out stems, doors, leaves, weed seeds and inorganic admixture | 10 20 | 47 21 | 58,1 29,0 |

Soybean flaps, its finely milled stems and weeds | 50 | 16 | 11,6 |

Middle parts of soy and weed stalks | 100 150 | 7 5 | 5,8 3,9 |

Large stalks of soy and weed plants | 200 | 4 | 2,9 |

This is a multicomponent mixture of soybean grain and crushed particles of stalks and leaves of soybean plants. The degree of grinding of soybean stalks from 2,9 до 58,1 times by 84%, consisting of particles of a small fraction of stems and leaflets up to 50 mm in length, and characterized by different speeds of drift. Full grain – 12...15 m / s; seeds with a broken part of the semiadult, shriveled, unfulfilled, eaten by pests – 8...13 m/s; crushed - 6,0…9,0; unrefined beans – 6...7; main crushed stems and leaves with a length of 20...50 mm – 1,8…3,0 m/s.

The separate feed of the milled heap from the first and second threshing drums to the first and second half of the rack mill provides a reduction in the load on the first half of the rack mill cleaning mill, on which the seed fraction of the grain is purified. At the beginning of the sieve comes a small heap, components of which were redistributed on the shaking board during movement. In the lower layer of the pile, most of it is ground soy grain, and straw impurities, as the easiest component, located at the top. For such enrichment of the lower layer of the grain does not require additional time, to pass through the sieve blinds.

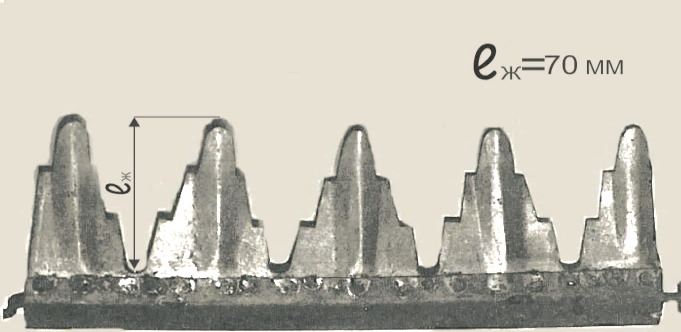

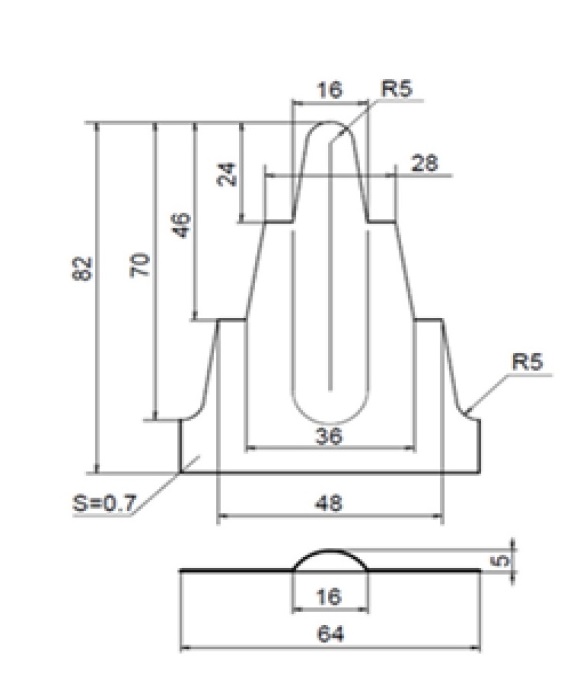

Figure 2 - Apparatus and dimensions of the harvester upper grating (ℓж=70 mm)

Figure 3 - Apparatus and dimensions of the harvester upper grating (ℓж=70 mm)

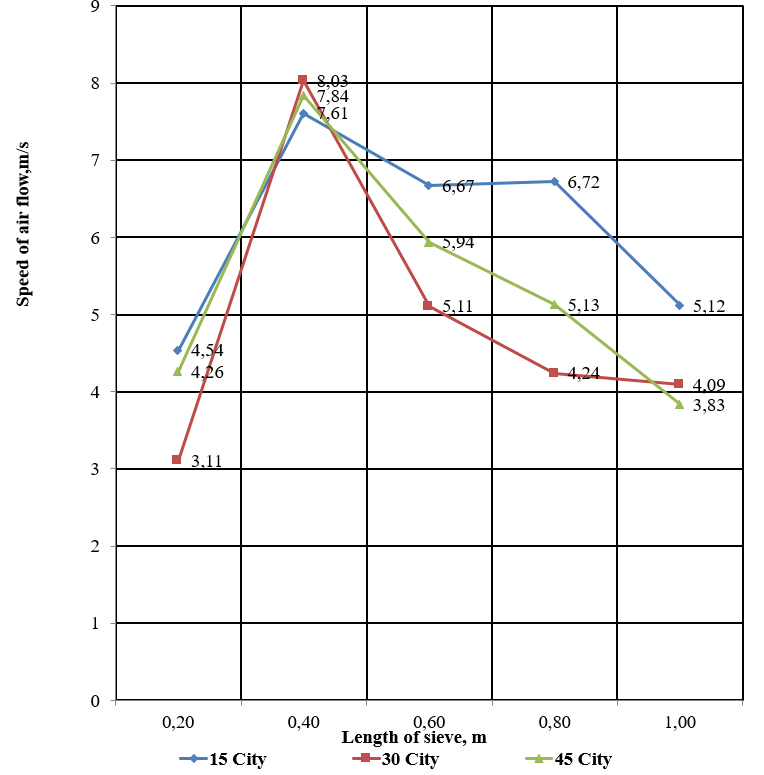

Replacement of the upper standard harvester cleaning grille (with 22 mm louvre petals) with a 70 mm louvre lattice and increase the gap between the louvre petals to 9 - 14 mm, based on increasing the angle of solution of slats of blinds from 15 to 45º, increases air flow speed significantly, and, respectively, its vertical component. As a result, a small pile of straw, being in a balanced state, actively loosened and blown out (blown away), that provides high-quality cleaning of seeds of the first fraction in the first half of the rack mill.

Figure 4 - Change in the speed of air flow along the length of the upper experimental grille, depending on the angle of solution of the slats of the blinds

Re-equipment of the two-phase mill harvester to create the optimal operating mode of the first 280 min-1 threshing drum , separate cleaning of small pile of milled first and second drums and separate collection of seed and commodity fraction in the two-section bunker of the combine and conducted research.

The experience of harvesting soybean combine two-phase threshing with a converted upper grille with elongated petals of blinds up to 70 mm showed, that the grain harvester cleaning system is able to separate and obtain quality seeds of the first fraction according to purity (table 4).

Table 4 - Weed and crushing content of the seeds of the first fraction

Plank solution angle blinds, º | 15 | 30 | 45 | 15 | 30 | 45 | 15 | 30 | 45 |

Speed of the second drum, min-1 | 540 | 600 | 660 | ||||||

Sore admixture in the grain of the first seed fraction, % | 0,16 | 0,20 | 0,21 | 0,26 | 0,19 | 0,18 | 0,11 | 0,22 | 0,23 |

Sore admixture in the grain of the first seed fraction, % | 4,87 | 4,63 | 4,45 | 5,37 | 5,21 | 4,93 | 4,14 | 4, 43 | 4,76 |

Fragmentation content in the grain of the first fraction, % | 5,16 | 5,32 | 6,91 | 7,61 | 6,93 | 5,32 | 6,28 | 9,12 | 8,87 |

Mistakes of experience: SX, g НСР0,5, g НСР0,5, % | – | – | – | 0,04 0,18 0,19 | – | – | – | – | – |

Separation of a small pile, in the first half of the harvester, he showed, that in the refined grain of the first fraction, the sorrel admixture according to the variants of the experience is from 0,11 to 0,26%. Due to the low humidity of soy seeds and stems during the harvesting period equal to 7,8 и 14,3%, in the first fraction of seeds in the variety Sentyabrinka there is an increased content of crushed grain, which, under optimal conditions, is from 5,16 to 5,32%.

The second commodity fraction of seeds, from the second half of the sieve, is more clogged due to insufficient airflow speed on the second half of the grille. Clogging of the second fraction on optimal modes is from 4,14 before 5,37% , which exceeds the permissible norm for littering and is subject to post-harvest work to obtain a seed fraction.

4. Conclusion

1. When threshing soy plants with a bile-type threshing machine, fractional composition of small soy pile is a complex mixture of particles, consisting of soybean, unrefined beans, bean flaps, crushed stalks of soy and weed plants, leaves of plants and weeds, seeds of weeds of different sizes and inorganic impurities:

- small soil and inorganic admixture with a length of 10...20 mm – 68%

- sour admixture of 50 mm in length – 16%

- average parts of stems of plants and weeds 100-150 mm – 12%

- large parts of stems of plants and weeds 200 mm – 4%

2. In the soy grain of the first fraction, the sorrel admixture in the seeds is 0,11-0,21%.

3. Increased crushing of grain in the seeds of the first fraction of the cultivar Sentyabrinka is caused by the low humidity of the grain and stems during the harvesting period equal to 7,8 and 14,3% and absence of weeds in soybean crops.