Современная архитектура электронной системы управления гибридного трактора

Современная архитектура электронной системы управления гибридного трактора

Аннотация

В работе предложена архитектура электронной системы управления (ЭСУ) для последовательного гибридного трактора с мотор-колесами или мотор-полуосями, решающая ключевые проблемы энергоэффективности и адаптивности в динамических условиях сельхозработ. Архитектура построена по доменному или гибридному принципу, где каждый домен использует наиболее подходящие коммуникационные протоколы, такие как Automotive Ethernet, CAN, CAN-FD и LIN, для обеспечения адаптивности и унификации, обеспечивающей совместимость компонентов. Ключевыми особенностями являются предиктивное управление ДВС с нелинейной моделью, оптимизирующее работу генератора в зоне максимального КПД (до 42%) и снижающее расход топлива на 12–15% при переходных нагрузках (например, смена транспортировка/вспашка), адаптивное распределение крутящего момента между мотор-колесами, уменьшающее энергопотери на 15–20% при работе на неоднородном грунте за счет минимизации пробуксовки, интеллектуальное управление тяговой батареей с активной балансировкой ячеек и предиктивной моделью Тевенина, повышающее точность оценки состояния заряда (SOC) до 98,5% и увеличивающее расчетный ресурс на 30%.

1. Introduction

The agricultural sector faces a difficult dilemma: the need to simultaneously increase productivity and reduce environmental impact. According to FAO data, agricultural machinery accounts for up to 15% of global CO₂ emissions, while traditional diesel tractors demonstrate extremely low efficiency, rarely exceeding 35–40%

, . These modest figures are explained by fundamental shortcomings of traditional powertrains: engine operation in suboptimal modes and significant energy losses in mechanical transmissions.In this context, serial hybrid systems with in-wheel motors and half-motors are of particular interest. Their fundamental difference lies in the separation of energy generation and conversion processes. However, in-wheel motors or half-motors allow for precise traction control at each wheel, unlike systems with axle motors, a single traction motor, or a dual-flow transmission. In such a system, the internal combustion engine functions solely as a generator, maintaining its operation in the peak efficiency zone, while the electric drive delivers torque to the wheel, providing precise traction control

, . This architecture opens up new possibilities for creating highly efficient agricultural machinery with minimal environmental impact.However, the practical implementation of these advantages faces significant technical challenges. Existing, outdated control systems are often unprepared for the dynamically changing conditions of agricultural operations. A typical example is the abrupt change in operating modes when switching from transport to plowing, leading to a significant (12-15%) increase in fuel consumption

, . Further complications arise from rigidly defined control algorithms that do not account for the variability of external conditions , as well as compatibility issues between components from different manufacturers. Studies in the field of individual electric wheel drive show the potential for significant efficiency gains through adaptive control .The aim of this work is to develop an adaptive and energy-efficient electronic control system (ECS) for a hybrid tractor with in-wheel hub motors. To achieve this goal, the following tasks must be completed:

– create a domain-specific ECS architecture based on modern networks (Ethernet, CAN, LIN);

– implement predictive engine control to ensure operation in the peak efficiency zone;

– implement adaptive torque distribution between the wheels to reduce slip;

– develop intelligent battery management with accurate state-of-charge assessment;

– ensure comprehensive thermal monitoring of components.

2. Research methods and principles

Modern vehicles utilize zonal, centralized, domain, or hybrid control architectures. With a zonal structure, the vehicle is divided into physical zones (left/right, front/rear), with each zone housing zonal controllers that control all devices within their zone. This structure reduces wiring length and improves energy efficiency due to shorter power lines, resulting in lower losses. The main drawback of this system is the complexity of implementing cross-zone functions, such as torque distribution.

A domain structure is preferable; it provides a modern approach to organizing vehicle hardware and software systems based on the separation of control functions by domain. Such systems rely on the separation of functionality:

– vehicle systems are grouped into separate areas, each responsible for its own area;

– centralized control: instead of multiple disparate control units, a smaller number of powerful computing nodes are used to handle tasks for the entire domain;

– and interface standardization: unified communication is used between domains (Automotive Ethernet, CAN, CAN-FD, and LIN).

The use of such an architecture is relevant for systems with individual wheel drive that require high-speed data exchange for slip control

.The developed electronic control system is a distributed computing platform integrating all components of the hybrid powertrain into a single, controlled system. Its key feature is the implementation of the principle of adaptive control with a closed feedback loop, where current system operating parameters are continuously analyzed and adjusted in real time.

The system is based on a domain network of electronic control units (ECUs) connected by a high-speed digital bus (CAN), Automotive Ethernet, CAN-FD, or, for less critical applications requiring speed and signal quality, LIN. CAN is a specialized industrial protocol, originally developed for automotive applications, providing reliable data transfer at speeds of up to 1 Mbps, deterministic response times, and immunity to electromagnetic interference.

Automotive Ethernet is a family of Ethernet protocols specifically designed for automotive communications. It is not a single protocol, but an entire system encompassing the physical and application layers. Its purpose is to ensure efficient and reliable communication between various electronic control units (ECUs), sensors, cameras, and other devices inside the vehicle. The technology is adapted for the automotive environment, taking into account harsh conditions, electromagnetic interference, and the special requirements for compact and lightweight wiring systems.

CAN-FD (Controller Area Network Flexible Data-rate) is an extension of the traditional CAN protocol. It was developed to provide higher throughput and data transfer flexibility in modern automotive applications. Unlike the traditional CAN protocol, which supports a fixed 8-byte data field, CAN-FD allows for data fields up to 64 bytes in size. This communication protocol can operate at higher speeds (up to 8 Mbps and sometimes higher), enabling faster communication between ECUs in modern vehicles. It is also worth noting that CAN-FD is backward compatible with the CAN protocol.

LIN (Local Interconnect Network) is a serial communication protocol designed to create low-cost local data exchange networks over short distances. It was developed as a complement to the CAN protocol in automotive applications where high data transfer rates are not required. This type of communication, unlike the ones described above, is implemented using a single wire. Each ECU performs specialized control functions for specific component systems (electric motors and transmission, safety, body electronics, communications and telematics, etc).

It is important to consider that the designed architecture of electronic systems for agricultural machinery must comply with a number of important domestic and international standards that ensure functional safety, environmental friendliness, electromagnetic compatibility, and reliability. ISO 25119 "Tractors and machinery for agriculture and forestry — Safety-related parts of control systems" establishes requirements for the functional safety of electronic systems at all stages of the agricultural machinery lifecycle. GOST R ISO 13849-1 Safety of machinery. Safety-related parts of control systems" plays an important role, defining requirements for the reliability of control systems. For hybrid powertrains, GOST R ISO 6469-1 "Electrically propelled road vehicles. Safety specifications" is mandatory, regulating the safety of high-voltage systems. The electromagnetic compatibility of electronic control units must comply with the international standard ISO 14982 "Еlectromagnetic compatibility of technical equipment. Agricultural and forestry machinery.

Test methods and acceptance criteria". Environmental requirements for internal combustion engines of hybrid tractors are defined by the GOST R ISO 8178 series of standards (emission standards) and GOST R 41.96 (Euro-5 and Euro-6 for mobile equipment). For autonomous control systems, the ISO 18497 standards "Agricultural machinery and tractors — Safety of highly automated agricultural machines — Principles for design" and ISO 12100 for general machine safety are relevant. In Russia, industry standards of the Federal Service for Veterinary and Phytosanitary Surveillance (Rosselkhoznadzor) and the requirements of the Technical Regulations of the Customs Union TR CU 010/2011 "On the safety of machinery and equipment" are additionally applied. When designing the architecture, the recommendations of SAE J1939 (CAN bus for agricultural machinery) and ISO 11783 (ISOBUS) for the unification of communication interfaces are also taken into account.

3. results and discussion

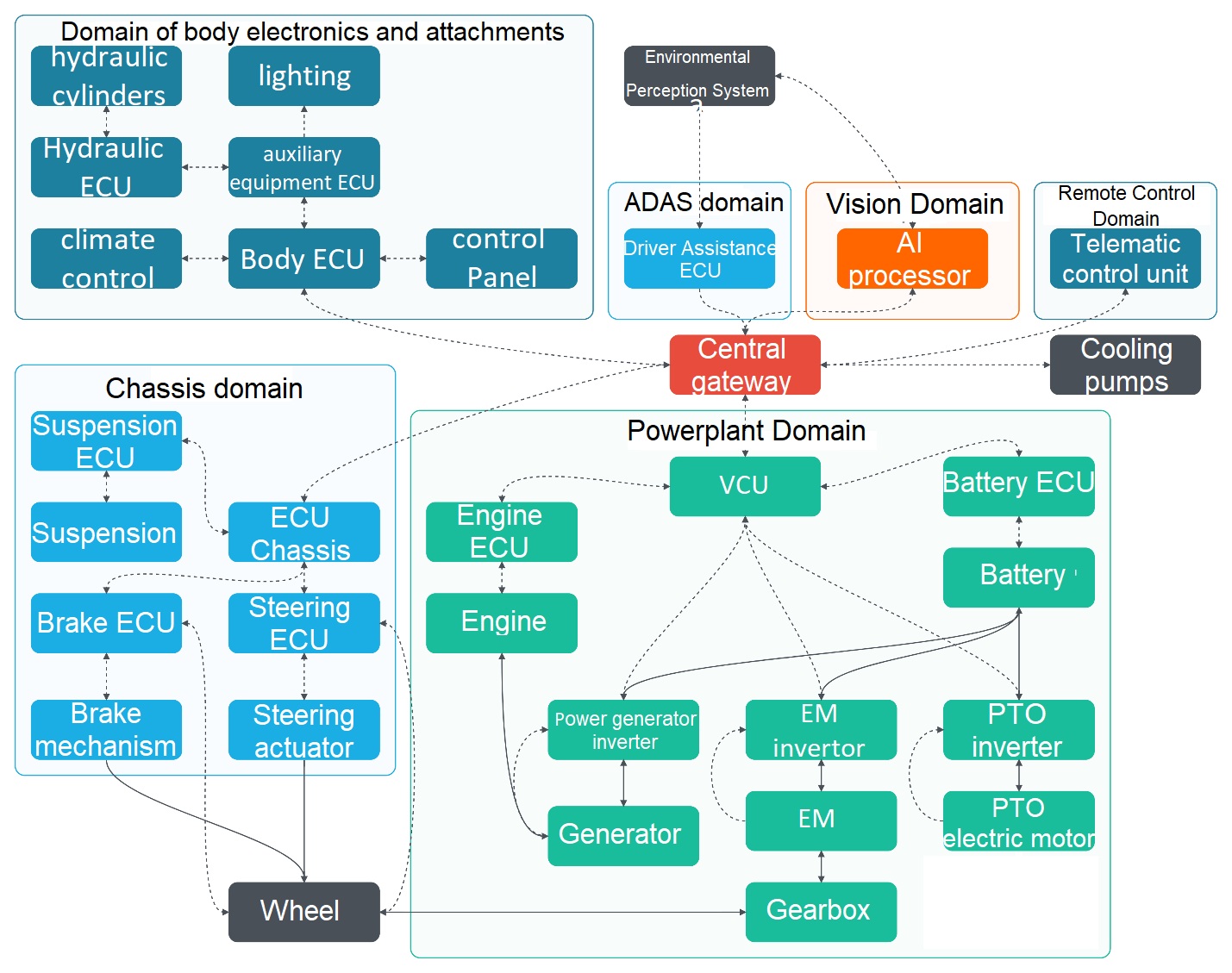

Figure 1 - Structural diagram of the electronic control system

Note: the dotted lines represent data links, and the solid lines represent power links. VCU – vehicle control unit; ECU – electronic control unit; PTO – power take-off shaft; EM – electric machine; AI – artificial intelligence; ADAS – Advanced Driver Assistance Systems

The vehicle control unit (VCU) plays a central role in the powertrain domain, coordinating the operation of the inverters controlling the electric motors, the high-voltage battery, and the diesel engine control unit. The latter ensures optimal engine operation through intelligent adaptive control and predictive monitoring. Methods of parametric diagnostics, such as the one proposed in

, can be integrated for accurate assessment of the condition and efficiency of the internal combustion engine as part of a hybrid power plant. The engine maintains a stable speed in the 1500-2000 rpm range, corresponding to the maximum efficiency zone, reaching 42%. This is made possible by the use of a nonlinear predictive control model combined with adaptive control, continuously optimizing operating parameters based on multiple factors, including the current generator load, battery charge state, cylinder pressure sensor readings, and lambda probe data.The electromechanical component of the system is based on synchronous-reluctance motors, either integrated directly into the wheels with a planetary gearbox or separated from the planetary gearbox by a constant-velocity joint for the steered wheels. Each electric motor is equipped with its own precision control system, including a transistor inverter with PWM modulation and precision rotor position sensors (resolvers). The system utilizes vector control — a method of monitoring and controlling electric motors that independently regulates the magnetic flux and torque of the motor. Unlike scalar control, which only controls the frequency and voltage amplitude, vector control operates on three key parameters: rotor flux linkage, torque, and rotational speed. The primary objective of this type of control is the mathematical transformation of three-phase system currents into a two-axis orthogonal coordinate system (usually a d-q system), where the currents can be independently regulated. This type of control not only ensures high energy efficiency but also the ability to adapt to changing surface adhesion conditions.

Figure 2 - Structural diagram of vector control

Under conditions of uneven traction (for example, on wet soil), the system redistributes torque between the wheels, reducing energy loss by 15-20%. The effectiveness of this approach is confirmed by experimental data obtained for the MTZ-82.1 tractor, where the introduction of the slip factor made it possible to optimize the operation of the drive

. The control system's time lag does not exceed 50 ms, ensuring the Nyquist condition is met for frequencies up to 10 Hz.The vehicle control unit also coordinates the operation of the high-voltage battery. The high-voltage traction battery's electronic control unit monitors cell parameters. Active balancing with an accuracy of ±5 mV is used to prevent degradation. A thermal model integrated into the ECU regulates the temperature within a range of 15-35°C using liquid cooling. Under peak loads (e.g., climbing a 20% incline, plowing, etc.), the system limits the discharge current, increasing battery life by 30% compared to passive control. Under peak loads, the ECU limits the depth of discharge to 70%, extending battery life. A predictive algorithm based on the Thévenin model estimates the remaining capacity taking into account charge/discharge cycles and temperature. The Thévenin model is written as follows:

where

The parameters of the Thévenin model for the entire battery discharge curve are determined using interpolation. Fixed parameter values at points on the discharge curve corresponding to specified state-of-charge levels

where

where

In model (1), the parameters

where

Here,

where

The traction battery ECU stores model parameters determined at the normal temperature (

– calculating linear relationships for parameters

– determining the coefficient

– and, based on the obtained coefficients, calculating

These parameters are used in the algorithm for estimating the battery's remaining capacity.

The vehicle's ECU determines the thermal management algorithm, ensuring stable operation of all hybrid powertrain components through intelligent temperature regulation. For the traction battery, the system maintains an optimal thermal balance by activating preheating at temperatures below 0°C and raising it to 15°C, which reduces battery degradation by 20% . In operating modes, liquid cooling maintains cell temperatures within the range of 25–35°C with a minimal temperature differential (no more than 3°C). Active cooling measures are provided for the electric motors and inverters: when the windings exceed 80°C or the power electronics exceed 60°C, ethylene glycol coolant circulation through aluminum radiators is activated. In emergency situations, when the temperature exceeds 100°C, the system automatically limits the power of the wheel hub motors by 50%, preventing overheating. This comprehensive approach to thermal management increases the overall reliability of the hybrid system by 25%, ensuring component longevity and stable operation under all operating conditions.

This same unit implements the principle of independent vector control of the traction electric motors through a fully electronic architecture. The system continuously analyzes data from numerous sensors, adapting control to changing driving conditions-variable loads, complex terrain, and various soil types. Intelligent algorithms ensure optimal torque distribution, combining high control precision with the energy efficiency of the powertrain. The elimination of mechanical components in favor of electronic control increases system reliability and simplifies maintenance. Integration with other tractor systems enables the creation of comprehensive solutions for precision farming, where both precision and energy savings are critical.

In hybrid vehicles, the VCU additionally functions as a regenerative braking control system. However, in agricultural conditions, the efficiency of regenerative braking is significantly limited. Low operating speeds (5-15 km/h) result in only 5-8% of kinetic energy being recovered during braking. Furthermore, the frequent stop-start nature of field work places increased stress on the traction battery, increasing the number of charge-discharge cycles and accelerating its degradation. Comparative studies of the parameters of tractors with different types of power units show that for low-power machines in closed spaces, it is preferable to use a pure electric drive or a hybrid scheme with the ability to operate only on electric traction

. These characteristics require specialized control algorithms tailored to the specific needs of agricultural machinery.The electronic chassis control unit coordinates the suspension, brakes, and steering using a sophisticated adaptive system that ensures safe and effective braking, dynamically variable ground clearance and suspension stiffness, and precise directional control of the vehicle. The module's operation is based on continuous analysis of data from high-precision sensors, including wheel speed sensors (0.1° resolution), inertial measurement units (±0.5% accuracy), and hydraulic pressure sensors (<1% error in the 0-300 bar range). This data allows the system to optimally distribute braking forces and adjust actuator operation in real time.

The body electronics and navigation control unit (BECU) performs comprehensive coordination of the tractor's auxiliary systems, ensuring operator comfort and operational efficiency. Unlike the VCU, this module integrates control of numerous peripheral systems — from basic lighting and climate control functions to modern multimedia systems and communications equipment and navigation

.The system features intelligent adaptation to operating conditions. Using data from network sensors and GPS navigation

, it automatically optimizes lighting parameters based on the time of day, weather conditions, and terrain. Particular attention has been paid to integration with precision farming technologies: the controller enables two-way information exchange between the attachment and the operator, displaying current operating parameters of agricultural implements (plows, seeders, sprayers) and providing an intuitive interface for control. This same unit manages the microclimate, maintaining optimal conditions in the operator's cabin by regulating temperature, humidity, and airflow . A distinctive feature of this system is its energy-efficient operating algorithm, critical for hybrid vehicles with limited battery power. The system continuously analyzes the current state of the power system, including battery charge level and combustion engine load. This data is used to intelligently control the climate control equipment — heating elements, ventilation systems, and cooling units. This approach minimizes the climate control system's energy consumption without compromising operator comfort.The electronic control unit for the body electronics and attachments serves as the primary interface between the operator and the tractor's systems. This module continuously collects and processes data from all sensors and subsystems, converting it into visual information on the display. The system provides operational monitoring of operating parameters, fault diagnostics, and control of key functions via an adaptive interface. A key feature of the system is its intelligent information filtering — the most important indicators are automatically highlighted based on the current operating mode. The ergonomic interface allows the operator to quickly access the necessary data without distracting them from driving. Integration with other systems via a digital bus ensures the accuracy and relevance of the displayed information in real time. This solution significantly improves the ease of operation and safety of complex agricultural machinery.

An ADAS (Advanced Driver Assistance System) in a domain architecture is a centralized computing device that processes data from the environmental perception system. The ADAS domain controller collects and analyzes data from sensors such as lidar, radar, and cameras. Based on this data, decisions are made in real time to guide the vehicle's movement. Data is integrated from multiple sources, allowing autonomous vehicles to navigate complex environments, detect obstacles, and respond to changing driving conditions.

The AI processor in hybrid tractors is a comprehensive platform that integrates precise positioning, intelligent routing, and energy-efficient motion control. This system is specifically designed for precision farming, which requires high precision with minimal energy consumption.

The solution is based on a multi-layered data processing architecture that combines signals from global navigation satellite systems with data from inertial sensors, lidar scanners, and cameras. This combination of information sources enables the system to adapt to changing operating conditions through the use of machine learning algorithms.

A key feature of the system is its ability to significantly reduce the energy consumption of the hybrid powertrain. This is achieved through intelligent selection of the optimal trajectory, precise synchronization of the traction motors, and predictive load on the tractor's energy system. This not only ensures high precision agricultural operations but also significant energy savings.

The remote control domain implements remote control of devices and systems via a dedicated unit over a fifth-generation (5G) mobile network. This is achieved through network architecture virtualization and network slicing. The goal is to create a universal digital infrastructure for IoT, artificial intelligence, autonomous systems, and other modern applications.

4. Conclusion

The study resulted in the development of a modern electronic control system (ECS) architecture for a series hybrid tractor, providing significant improvements in energy efficiency and adaptability. The following objectives were successfully addressed.

1. A domain-specific ECS architecture was developed based on specialized protocols (Automotive Ethernet, CAN, LIN), ensuring hardware unification, component compatibility, and high data exchange speeds.

2. Predictive engine control with a nonlinear model was implemented, allowing for generator optimization in the peak efficiency zone (up to 42%) and a 12–15% reduction in fuel consumption under transient loads.

3. Adaptive torque distribution between the in-wheel motors was implemented, minimizing slippage on uneven soils, reducing energy losses by 15–20%.

4. An intelligent traction battery management system was developed using active balancing and the Thévenin predictive model. This increased the accuracy of state-of-charge (SOC) assessment to 98.5% and increased the estimated battery life by 30%.

5. Comprehensive thermal monitoring of power components was ensured, increasing the overall reliability of the hybrid system by 25% by maintaining optimal temperature conditions.

The developed system optimizes energy flows, reduces CO₂ emissions, and improves the reliability of the hybrid powertrain, making it a promising solution for precision farming applications.